How It Works Green Processing

Wild Burro Processing is committed to processing ore into various products in a clean, green, organic way, without toxic leaching chemicals, such as cyanide and mercury, as most processing facilities do. We detox the end product, and smelt them to become pure, whether that is organic brick or precious metals.

Mining Ore

Ore is acquired through mining sites that are either patented or leased from the Bureau of Land Management. The ore is then excavated, then crushed, then super-sacked and transported to the processing facility.

Milling Ore

After delivery to the processing facility, it is reduced in size further, first by a hammer mill, then a ball mill, then mixed with water in a super bowl concentrator to get it to nano size and pull out free metals.

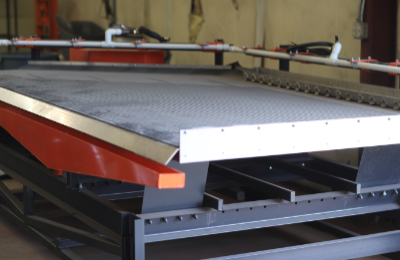

Concentrating

Once its been milled to nano size particles, the various metals are separated using a shaker table to create a concentrate, then dissolved into solution and refined in electro-winning tanks.

Smelting

The metal goes back and forth between the electrowinning tanks and the induction furnace to reduce impurities. Then they are poured into molds for dore’ bars and sent to the refinery to become bullion.

Clean. Green. Organic

Wild Burro Processing is committed to develop natural resource products that are pure, organic, detoxed, clean, green, and environmentally safe for the world we live in, both in the end product and the way we process them.