How It Works:

Milling Ore

Once at the production facility, it is put through a hammer mill to reduce it down to 200 mesh minus in particle size, then fluxed and roasted to reduce ore to an oxide.

It is then ball milled with steel balls to a nano particle size, to achieve the highest yield and also the highest concentration level of whatever metal or element is desired to be processed.

There is no cyanide or toxic methods used in this process.

The ore is then mixed with water and added to a Super Bowl Concentrator to pull out the free metal in the ore.

Milling Ore

After the ore is delivered to the processing facility, the ore is milled. Milling the ore involves getting the ore into a smaller and smaller particle size, so that it can be concentrated.

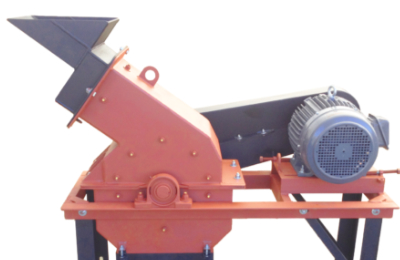

Hammer Mill

After the ore has been crushed at the mine site to a quarter inch minus, then it is further crushed to 200 mesh minus, and then roasted to increase yield of the metal desired.

Ball Mill

The ore is then put into a ball mill that uses steel balls rolling with the ore to bring it to a nano particle size, enabling more precious metal extracted to a higher concentration.

Super Bowl Concentrator

The ore is mixed with water and added to a super bowl concentrator, which uses water and gravity to pull out free metals from the ore.

Clean. Green. Organic

Wild Burro Processing is committed to develop natural resource products that are pure, organic, detoxed, clean, green, and environmentally safe for the world we live in, both in the end product and the way we process them.